Let Our Aerosol Packaging Machine Deliver the Service and Quality To Aerosol Can Manufacturers’ Products In Pakistan!

Buy Specialized Aerosol Can Filling Equipment Offering Extraordinary Quality And Durability

- Our Spray Paint Can Filling Machine Colors Your World with Proficiency. Now Experience the Future of Spray Paint Packaging with Us

- Our Aerosol Paint Filling Machine Offer Precision in Every Shade. Now Lift up Your Aerosol Paint Production with Top-tier Machinery

- Our Aerosol Semi Automatic Can Crimping Machine Seal the Excellence. Now Get Perfect Crimps for Aerosol Production

- Our Bag On Valve Filling Machine Innovate with Every Spray. Now Transform Packaging with Our BOV Aerosol Filling Fineness

Pull Up Your Game Of Production – Get Quote For Aerosol Spray Paint Can Filling Machine Price For Sale & Turn Ambition into Airborne Skill

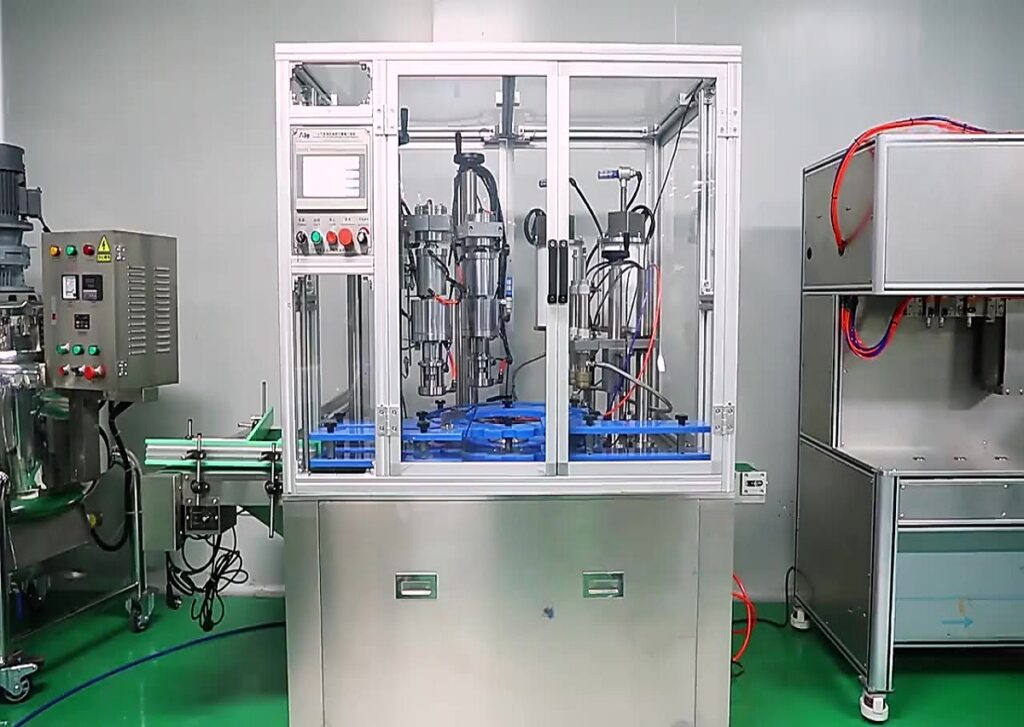

Automatic Aerosol Filling Machine

Semi Automatic Aerosol Filling Machine

The Manual Aerosol Filling Machine

The Aerosol Can Making Machine

The Spray Painting Air Compressor

The Aerosol Air Compressor

Let Us Empower Your Brand with Quality: Explore the Unmatched Features of Our Aerosol Spray Painting Air Compressor

Adaptable to Various Can Sizes and Volumes

Revo’s Aerosol Packaging Machine is engineered for adaptability that effortlessly accommodate a broad spectrum of can sizes and capacities. Our versatility facilitates seamless transitions between different product lines and enhances operational efficiency. It enables manufacturers to respond rapidly to market demands and packaging supplies.

Higher Safety Mechanisms

Protection is at the forefront of our design viewpoint. So, our aerosol filling machine features comprehensive safety mechanisms to protect operators from potential risks. However, these built in safety features ensure a safer working environment by reducing the risk of accidents and promoting a safety culture within the production facility units.

Cutting Edge Sealing Technologies

Revo’s machine integrates hi tech sealing equipment that deliver superior seal integrity. It is a critical factor in preserving product quality and extending shelf life of product. Our advanced sealing solutions safeguard the contents and reinforce consumer trust by ensuring consistent product performance and consistency.

Spontaneous Operation Panels

Intended with the operator in mind our spray paint machine boasts intuitive operation panels that simplify complex procedures. However, friendly interfaces shorten the learning curve for new operators by reforming manufacturing operations and reducing downtime associated with staff training and process adjustments. Higher productivity and efficiency on the production ground.

Fill Your Product with Unmatched Quality and Modernization of Aerosol Can Filler! Now Choose Us Means Choose Excellence

Transform & Revive

Health & Safety Promise

Green & Clean Environs

Bag On Valve (Bov) Aerosol Filling Machine System Innovations

Benefits of our BoV technology:

- Integrity of Product: It Keeps the fuel separate from the product ensures purity and eliminates contamination perils.

- Consistency of Temperature: The dispensed product maintains a temperature closer to ambient as the propellant is gentler and enhance user wellbeing.

- Eco-Friendly Propellants: Revo’s system accommodates milder propellants and prioritize user safety and environmental concerns.

Initial Can Placement | Begins with placing empty aerosol cans onto the production conveyor. |

Filling with Product | Uses either pneumatic or hydraulic metering systems to add the product into cans. |

Valve Installation | Valves are fitted onto cans using an automated system. |

Securing the Valve | The process of crimping ensures that valves are securely attached to cans. |

Adding Propellant | This step involves the injection of the appropriate propellant into the cans. |

Quality Assurance | Includes leak detection and weight verification through the use of water baths and weight checkers. |

Fixing the Actuator | Attaching actuators to valves is done automatically. |

Attaching the Cap | Caps are organized, directed, and placed onto actuators using a machine designed for capping. |

Production Output | The automatic lines are equipped to handle up to 3600 cans each hour accommodating aluminum or tinplate cans with diameters of 35-66 mm and heights ranging from 80-350 mm. However, semi automatic setups aim for a daily output of 4000-8000 cans. They are suitable for 35-66 mm diameter aluminum or tinplate cans and 80-350 mm in height. |

Automotive Industry

Aerosol packaging and filling machine is pivotal in ensuring product quality and longevity in the competitive automotive industry products. You can package lubricants, paints, or cleaning agents. Thus, our machine ensures each canister is filled accurately and sealed perfectly. We guarantee the product’s reliability and usefulness. So, automotive professionals trust us to provide packaging solutions that meet their industry’s demanding standards. We enhance both product performance and satisfaction of consumer.

Furniture Products

Industrial Coatings

Personal Care Products

Our Automatic Aerosol Filling Machine Services

Customization & Design

Installation & Commissioning

Support & Training

Spare Parts & Logistics

Advisory & Consultation

Contact Us for Aerosol Can Making Machines

Get in Touch Via

- Phone: Call us at 0321-4668336 or 0333-4667750

- Email: Send your inquiries to: info@revo.com.pk

- Visit Our Office: 31-E, Majid Street, Umer Town, Industrial Area, Sherakot Bund Road, Lahore